x-net® C22 dry system wall heating

Discover how easy it is to install.

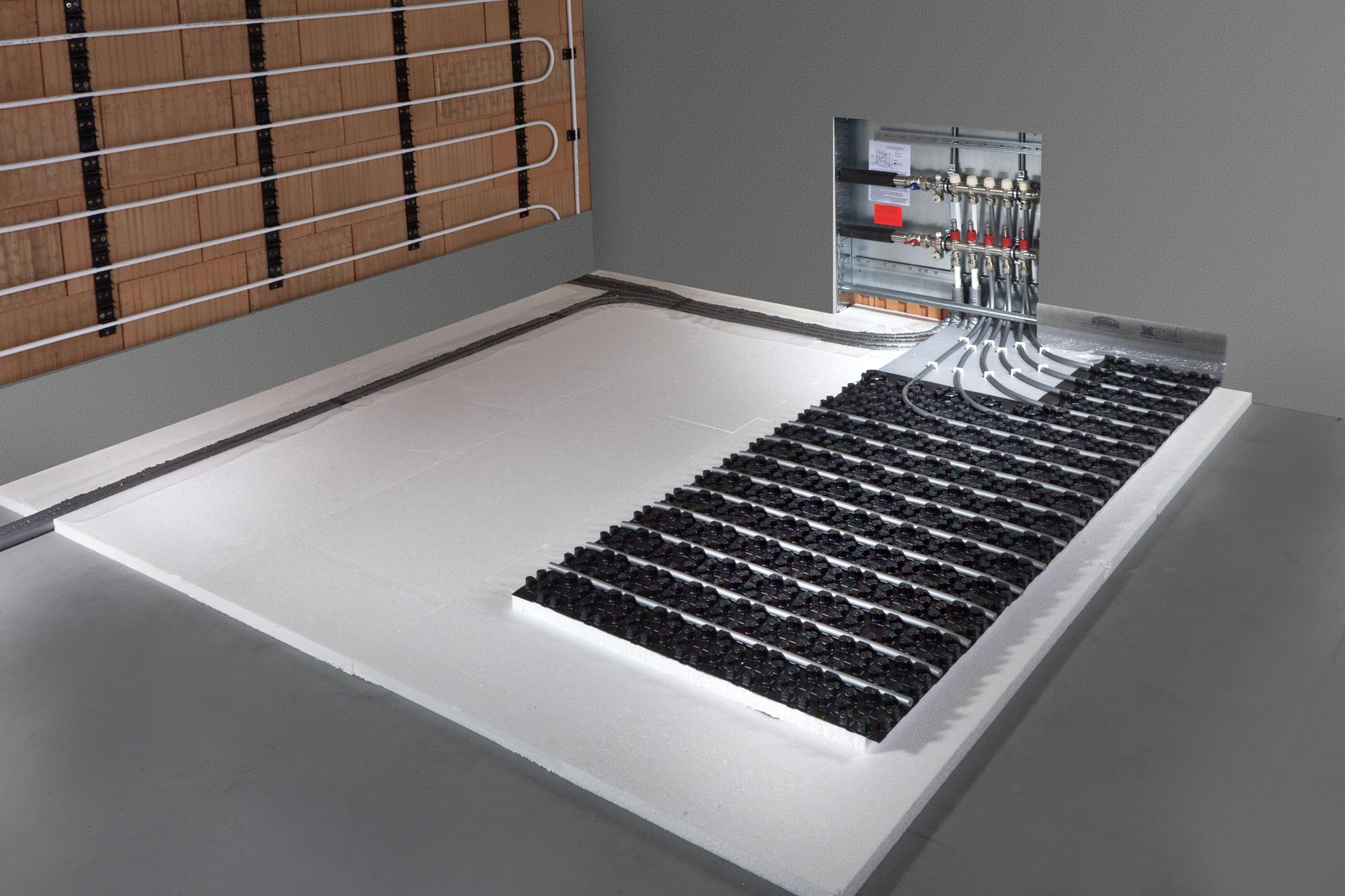

The perfect wall heating for dry construction. Panel heating is definitely the right choice when the priority is to keep system temperatures low while ensuring the optimum level of comfort in living areas or rooms that serve a similar purpose. Depending on the situation, wall heating is a great alternative or an ideal supplement to underfloor heating. It can be used when the floor coverings have a high level of thermal resistance (e.g. in the case of wooden flooring), if the existing floor coverings are to be retained during refurbishment, or if – for example – the underfloor heating in the bathroom is not powerful enough. The x-net C22 dry system wall heating is ideal for use as panel heating/surface cooling on all walls that provide firm support over the entire surface and feature panelling made of plasterboard, fibre-reinforced plasterboard, or other dry wall elements suitable for wall heating.

Advantages

x-net C22 dry system wall heating

- Radiant heat

- Low flow temperatures

- Minimal pipe covering ensures a quick response

- Can be easily combined with underfloor heating

- The pipe dimension of 14 x 2 means that wall areas measuring up to 10 m² can be occupied by an individual heating circuit

- Reliable venting due to the pipe dimension of 14 x 2

- Single connection or connection to the heating circuit manifold in the Tichelmann system

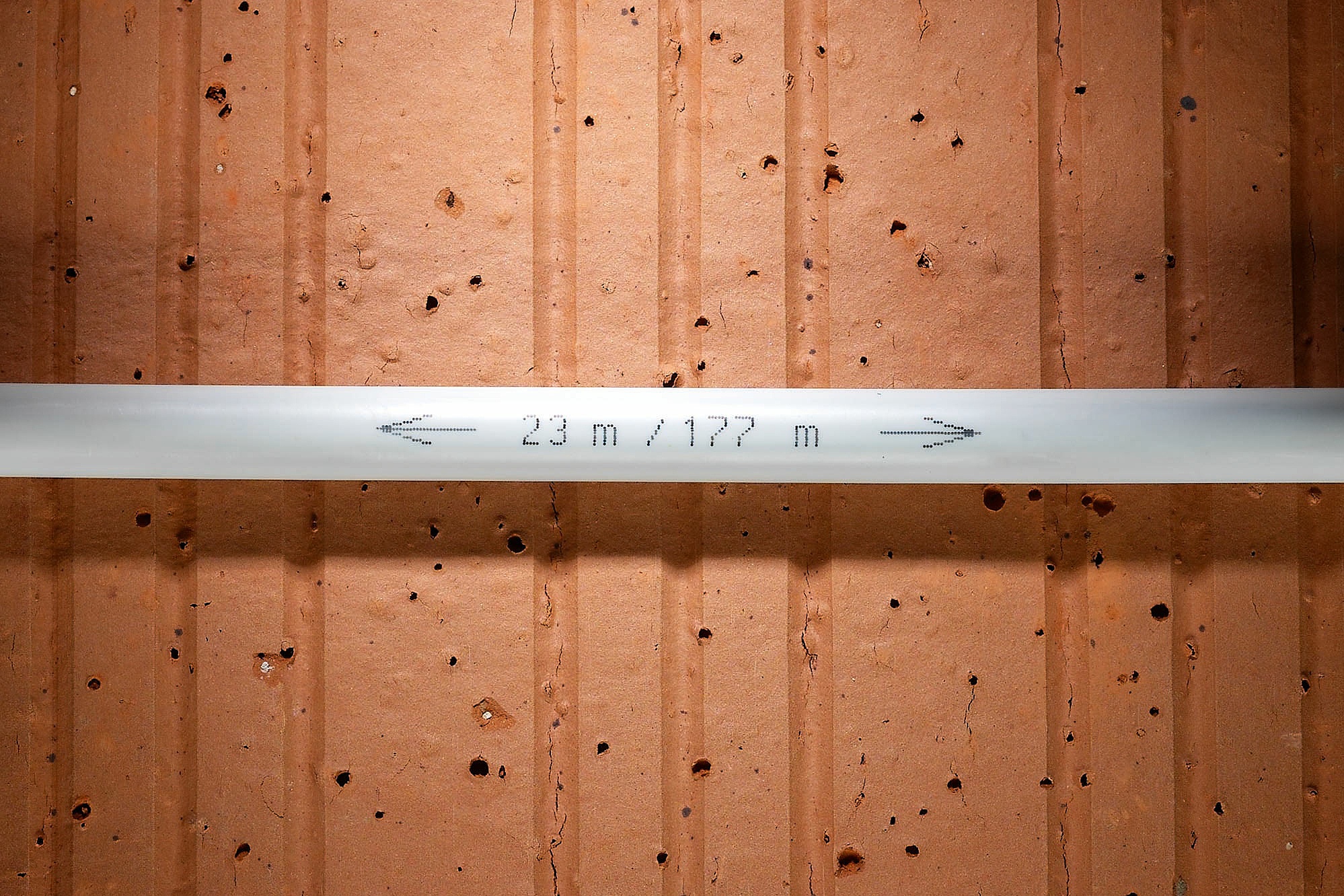

- Easy-to-handle MKV composite pipe that is 100 % oxygen diffusion-proof

- Pipe run of the fully installed wall heating can be made visible with x-net thermofoil

- Drywall construction method without any drying times, no moisture in the structure

x-net C22 dry system wall heating

x-net MKV composite pipe

x-net wall heating connection

Accessories

Documents

Product video

For new and old buildings. Comfortable heat from the wall delivered in no time.

- The pipe dimension of 14 x 2.0 mm means that wall areas measuring up to 10 m² can be occupied by an individual heating circuit

- Reliable venting due to the pipe dimension of 14 x 2.0 mm

- Single connection or connection to the heating circuit manifold in the Tichelmann system

- Easy-to-handle MKV composite pipe that is 100 % oxygen diffusion-proof

- Drywall construction method without any drying times, no moisture in the structure

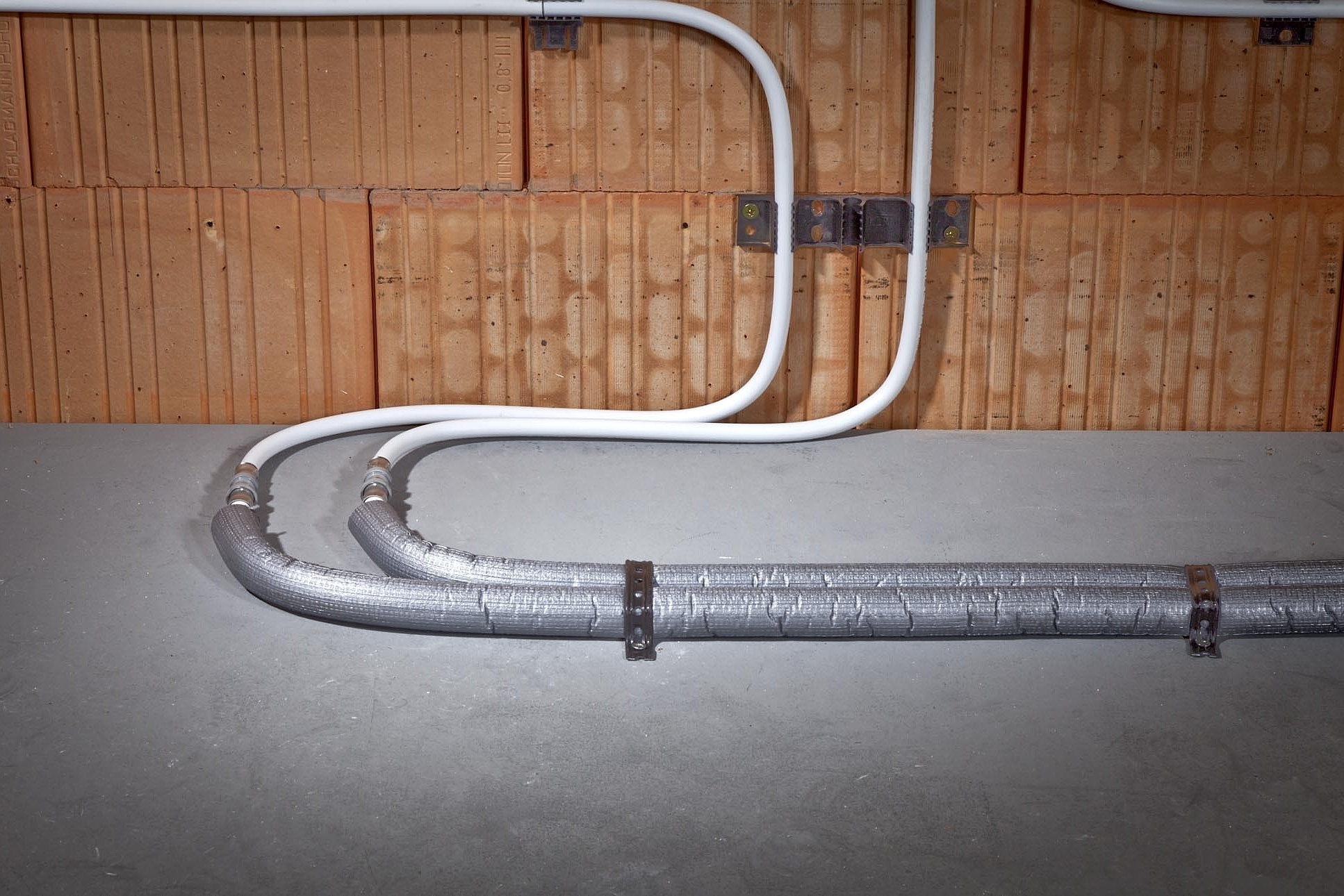

x-net unrolling unit

Lay your ventilation and underfloor heating pipes faster, smarter, and more effectively. The handy unroller for both types of pipe!

- Reduces installation work and helps keep the construction site tidy

- Ventilation and underfloor heating pipes can be laid by a single worker

- No tension or twisting during unrolling

- Can be assembled and disassembled in just a few simple steps without the need for tools

x-net Sicherheitscutter

KERMI x-net Sicherheitscutter für Folien und dämmstofffreie Verlegesysteme. Das Spezialmesser mit verdeckter Klinge ermöglicht das sichere Öffnen von Stretchfolienverpackungen und Kartonagen ohne den Inhalt zu beschädigen.

Auch geeignet für dämmstoffreie x-net Verlegesysteme aus PE-Schaum bzw. Panels bis 3 mm Dicke.