Valve technology & hydraulic balancing

Valve technology for radiators

Hidden behind the thermostatic sensor head is the actual valve – which, although invisible from the outside, is still a significant component in the radiator functioning as it should.

State-of-the-art valve technology ensures extremely accurate adjustability, thermal comfort, and energy efficiency in every valve radiator from Kermi.

As a result, Kermi is setting new standards in radiator valve technology – particularly when it comes to simplifying hydraulic balancing.

General information on hydraulic balancing

Hydraulic balancing of pipelines in buildings is essential from a financial and ecological perspective. It is also required in the applicable DIN standards and directives. Only a radiator with enough heating water flowing through it can provide the necessary heat output.

Hydraulic balancing involves limiting the volume flow of the heating water to the value that corresponds to the heat demand of the individual radiators in the system. Every heating system with physically separate heat generation and heat dissipation to the area being heated is confronted with the problem of heat distribution in line with demand.

Today’s conventional pump hot water systems are designed to distribute the heat evenly according to the demand from all the rooms being heated. This heat distribution requires a water flow rate that is distributed according to the heat output in the pipe system – but unfortunately, it is rare that the water flow rate actually meets this level. According to the principle of least resistance, the heating water from the heat source flows back to the heating centre via the shortest path.

This path usually leads through the radiators situated nearest to the circulation pump in the pipe system. As a result, radiators that are further away from the heating centre in a hydraulically unfavourable position end up having an inadequate amount of heating water flowing through them. Consequently, rooms that are further away are inadequately heated or rooms near the heating centre become overheated.

Experience shows that this problem is often incorrectly assessed. In many cases, pumps that are too small, flow temperatures that are too low, or a heat generator that is too small are diagnosed as the supposed cause of insufficient heat distribution. This results in pumps that are too large being installed, the flow temperature being set too high, or the heating control being misaligned.

The effects of this are flow noises in the heating system, overheated rooms, and rooms with an inadequate supply of heat. What’s more, these effects are associated with increased consumption of the energy required to generate and distribute heat. Hydraulic balancing – that is, setting the correct kv values and thus generating virtually the same resistance levels for all radiators in a heat distribution network – is the only way to solve this problem with the most efficient use of energy.

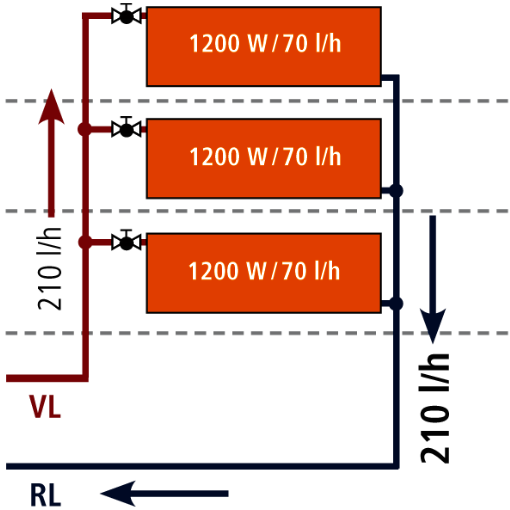

System with hydraulic balancing performed correctly

A correct kv setting on the valve ensures even distribution of the heating water.

Performed at the factory in the case of Kermi valve radiators for conventional systems.

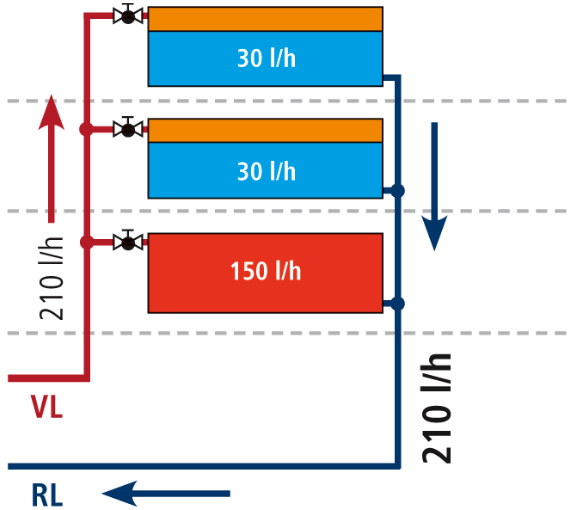

System without hydraulic balancing

kv setting on valves set to “fully open”

The bottom radiator (red) is oversupplied, while the top radiators are undersupplied.

The benefits of hydraulic balancing

- Energy savings (up to 6 %)

- Environmental protection (CO2 savings)

- Comfort (no excess or inadequate supply, no noises from the radiator)

- Meets the corresponding regulations and their control via documentation (e.g. energy pass, EN 15378, EN 18599)

- Meets the obligation for hydraulic balancing according to German Construction Contract Procedures (VOB) and the German Energy Saving Ordinance (EnEV)

- Uses the efficiency provided by energy-efficient heat generators

Hydraulic balancing and KfW (German Reconstruction Loan Corporation) subsidies

Valve presetting at the factory is a recognised approximation process for hydraulic balancing of the radiator valves in accordance with the performance specification provided by the Union of German Central Heating Management (VdZ e.V.). This means that the requirements for current state subsidy programmes, such as KfW (German Reconstruction Loan Corporation) are met.

Kermi valves with factory presetting

Features and benefits

Kermi valve radiators are equipped with a preset, adjustable valve insert at the factory on the basis of their heat output. With the valve inserts fitted as standard, eight main kv settings and seven intermediate settings can be made.

To retain the control quality across the entire output spectrum, fine control inserts are used for small radiators.

For the factory kv preset, five of the possible 15 settings are used.

The kv factory presetting is made with conventional heating systems in mind (in detached and semi-detached houses, for example), where the differential pressure (Δp) is 100 mbar.

Tip for the one-pipe system:

If the radiators with integrated valve are used in a one-pipe system, the valve insert should be turned to position “8”.

Valve insert V3K / V4K / V6K-S

- With eight main settings and seven intermediate settings for possible kv values

Continuously opening adjustable flange, enabling infinite adjustment

- Finer adjustment possible

- Inserts are easier to clean (rinse)

- Less susceptible to problems

Two different valve sizes

- Better control quality, even for small radiators

Colour-coded valves according to kv value

- kv value can be identified immediately

- Spare part (always supplied fully opened) can be easily adjusted

Certification according to EN 215

- Registration number 6T0002 + 6T0006

- Virtually ideal hydraulic balance for heating systems with up to 500 m² of effective area or with a total length of all sections in the flow and return of less than 100 m.

- On average up to 6 % energy savings.

- Meets the obligation for hydraulic balancing according to VOB (German Construction Contract Procedures) part C/DIN 18380.

- Meets the obligation of the German Energy Saving Ordinance (EnEV) for the implementation of hydraulic balancing.

- Meets subsidy requirements for KfW (German Reconstruction Loan Corporation) and BAFA (German Federal Office of Economics and Export Control). No subsidies or credits without hydraulic balancing!

- Positive effect on the building energy pass.

- Proper operation of the heating system.

- Better level of customer satisfaction – fewer complaints.

- Time savings for designers and specialist partners.

Screw connection with integrated valve insert

The valve shut-off block for Kermi radiators with a 50 mm connection

Kermi provides a valve shut-off block as an accessory for all radiators with a 50 mm connection. This creates an alternative screw connection with an integrated valve insert and adjustable bypass for switching from two-pipe to one-pipe operation. Angled and straight versions are available, each supplied with a decorative cover as standard. This turns a compact design into a valve radiator with high-quality connection technology that works in perfect harmony with the radiator.

- Integrated valve insert, flowing from both sides, i.e. flow is possible on the left or right side

- Lockable bypass function, for two-pipe and one-pipe systems

- Connection dimension 50 mm, radiator shutoff via valve and spindle

- Angled or straight version, supplied with cover as standard

- Cover in white (RAL 9016), chrome, or stainless steel look

Kermi valves with dynamic flow control

Features and benefits

As soon as values start deviating from the design basis (full capacity), it does not take long for even hydraulically balanced systems to reach their limits.

Particularly during peak times when heating demand spikes temporarily (in the morning or evening, for example), perfect balancing is no longer a given. If the thermostatic valves on several radiators all open at the same time, the first radiator in the loop can be oversupplied and radiators further down the loop can be undersupplied due to differential pressure fluctuations. As a result, the undersupplied radiators do not heat up properly.

Users react to this by turning up the heating thermostats – something which, over the course of the day, results in overheated rooms as soon as the heating demand normalises again. This then leads to frequent complaints by customers or tenants.

Another aspect which needs to be taken into consideration is the fact that there is a lack of information about the pipe system in existing buildings undergoing refurbishment. It takes a disproportionate amount of effort in these cases to carry out hydraulic balancing.

Using the V7K-L valve with dynamic flow control ensures that hydraulic balancing doesn’t just apply to the design basis – it performs well in practice too. The valve controls the maximum flow independently of the actual differential pressure or any differential pressure fluctuations that may occur during peak times, and prevents radiators being oversupplied.

In most cases, this does away with the need for the differential pressure controllers that are normally found in the individual loops.

As it is no longer necessary to determine the individual, differential pressure-dependent adjustment values for the individual radiators, time savings can also be achieved.

Please note:

A mixed installation consisting of valve inserts with kv presettings and a V7K-L valve insert is not recommended.

- Even supply for all radiators in the loop.

- Prevents complaints from customers or tenants.

- Supports trouble-free operation even for existing buildings with an unknown pipe system.

- Practical hydraulic balancing.

- Costs savings generally achieved as a result of differential pressure controllers becoming superfluous.

- Time savings as there is no longer a need to determine individual, differential pressure-dependent adjustment values for individual radiators.

Screw connection plus integrated valve insert with dynamic flow control

The valve shut-off block for Kermi radiators with a 50 mm connection

Kermi provides a valve shut-off block as an accessory for all radiators with a 50 mm connection. This creates an alternative screw connection with an integrated valve insert that features dynamic flow control. Angled and straight versions are available, each supplied with a decorative cover as standard. This turns a compact design into a valve radiator with high-quality connection technology that works in perfect harmony with the radiator.

- Integrated valve insert with dynamic flow control

- Connection dimension 50 mm, radiator shutoff via valve and spindle

- Angled or straight version, supplied with cover as standard

- Cover in white (RAL 9016), chrome, or stainless steel look